Without a doubt, technology has reshaped operations across several industries over the years, bringing more efficiency into business. However, the current global pandemic, accompanied by changes in consumer demand and the economics of supply and demand, will fundamentally alter the manufacturing industry.

As such, there are rapidly evolving manufacturing technologies poised to reshape the entire industry to meet new demands. Therefore, what trends should you expect from the manufacturing industry in the future? Below are some specific insights into what the future holds for the manufacturing sector.

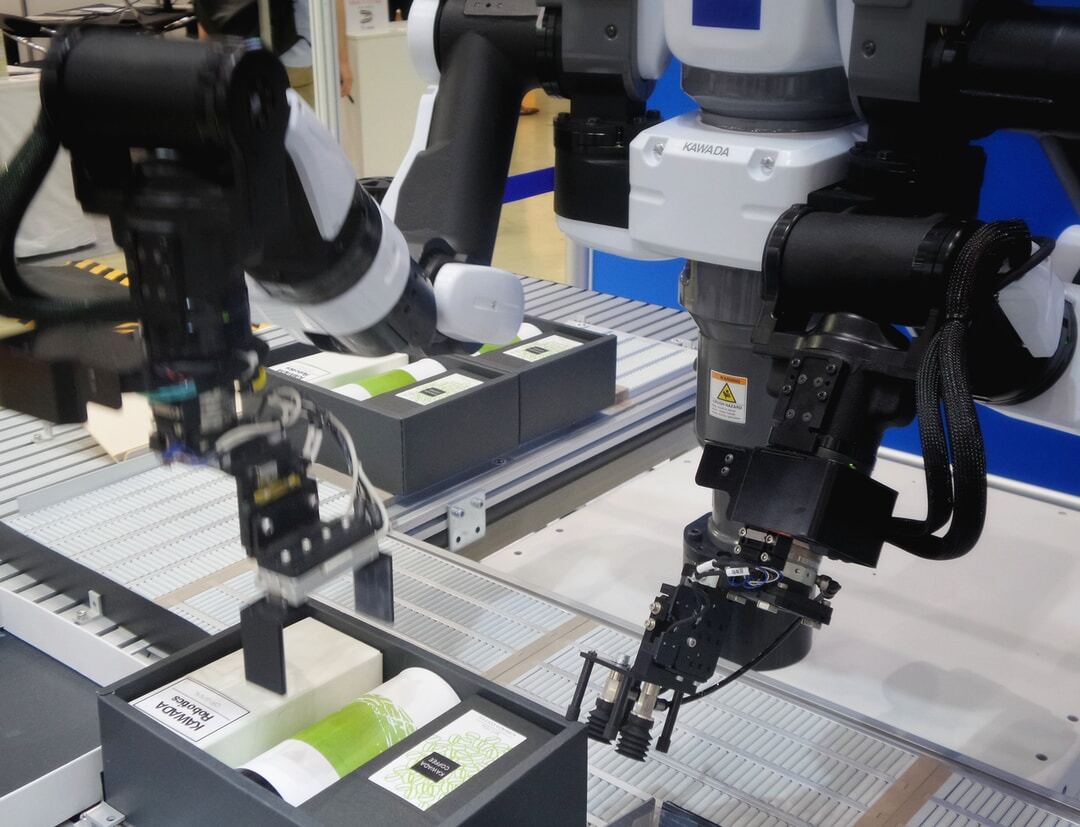

Greater automation in factory operations.

The COVID-19 pandemic undoubtedly exposed the fragility of depending on labor in the manufacturing sector. Consequently, many experts predict that we’ll see a high increase in the caliber and frequency of technology applied in the industry. Some of these technologies include machine learning, cloud computing, sensor usage, edge computing, and computer vision. There’ll also be increasing integration of robots into the manufacturing operations. Robots are beneficial in this industry and can perform several mundane tasks ranging from sorting to packaging. Therefore, companies in the industry can benefit from using various automated equipment to introduce efficiency in the production process. Reputable packaging automation brands such as Insite Packaging can help with this need.

Insite Packaging produces sealing equipment and case erecting to make the packaging process more effective. Their robotic case erector machines transform case blanks into completely erected ones with sealed bottom flaps in a fast and easy-to-operate manner. Their automatic case erectors’ active case squaring feature ensures that all cartons are continuously adjusted into square cases before they’re sealed. Additionally, Insite Packaging’s box erectors produce square, bottom-sealed cases, that are durable and of the highest quality because industry-leading engineers and product specialists design them. What’s more, their carton erector also comes with advanced motion-controlled software, so the packaging process requires fewer parts, less maintenance, creating smoother operations, quicker changeovers, and more dependable performances.

Better investment in the workforce.

Many experts believe that automation’s introduction into the manufacturing workspace will create various new working opportunities for employees. Deloitte projects that nearly half of the manufacturing jobs needed over the next ten years won’t be filled, as there’s an increasing shortage of skilled, qualified employees in the industry. Therefore, manufacturing companies will likely give their employees more learning opportunities through retraining and helping them learn new vocational or trade skills.

This way, these companies can empower their current workforce and also attract new talent. Workers will be trained to adapt to new technologies in the industry, familiarizing themselves with the presence of machine learning and automation tools. As such, their skill sets will be expanded, leading to potentially better, high-paying jobs for factory employees. Several billionaires and philanthropists like John Arnold and Laura Arnold, who started the John Arnold Foundation, may even push for a better retirement policy in the industry under better job opportunities, granting the factory worker more chances to retire with dignity and financial security.

Expect an increasing focus on sustainability.

It’s no secret that the manufacturing industry has been one of the most notorious contributors to environmental degradation over the years. As the world becomes increasingly climate-conscious, many experts predict that manufacturers will be forced to put more effort into limiting the industry’s high waste volumes. More “green jobs” will likely be created in the industry. Many local, smaller, and energy-efficient factories will pop up to reduce energy consumption due to prolonged transportation of goods to customers.

The manufacturing industry will significantly change as we progress due to advances in technology, the pandemic’s aftermath, and other vital factors. The points above are critical changes that experts believe will likely occur in the sector over the coming years.